Key Takeaways

- Essential for Automation: PLC programming software is vital for automating industrial processes and enhancing operational efficiency.

- User-Friendly Features: Tools with intuitive interfaces, real-time monitoring, and advanced debugging streamline programming tasks and reduce downtime.

- Multiple Language Support: It accommodates various programming languages such as Ladder Logic and Structured Text, allowing flexibility in system design.

- Key Benefits: The software increases efficiency, accuracy, and flexibility while offering real-time performance monitoring and support for multiple communication protocols.

- Strategic Selection: Choosing the right PLC programming software requires considering compatibility, cost, and vendor support to align with organizational goals and improve processes.

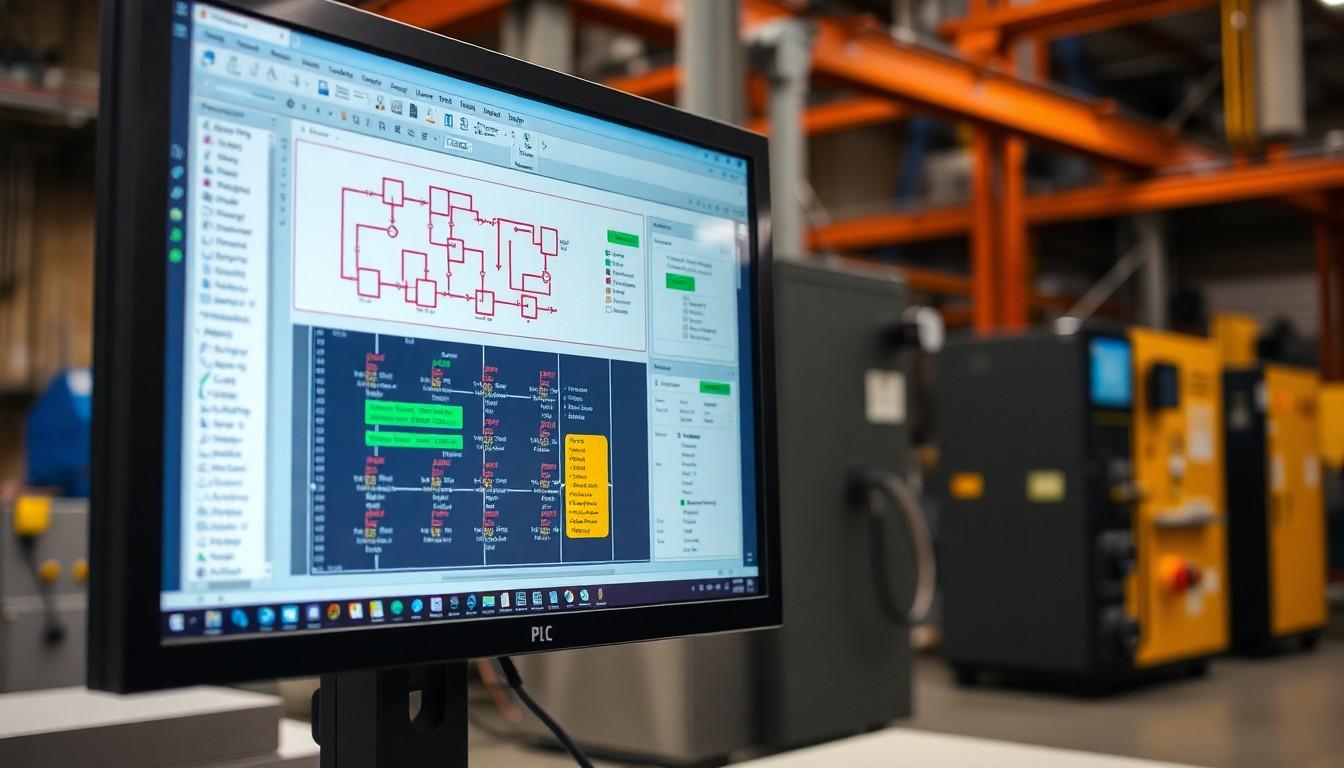

In today’s fast-paced industrial landscape, PLC programming software plays a crucial role in automating processes and enhancing operational efficiency. These powerful tools enable engineers and technicians to design, implement, and troubleshoot control systems with ease. As industries increasingly rely on automation, understanding the capabilities of PLC programming software becomes essential for staying competitive.

From intuitive user interfaces to advanced debugging features, the right software can significantly streamline workflow and reduce downtime. With numerous options available, selecting the best PLC programming software tailored to specific needs can be a game changer. This article explores the key features, benefits, and considerations when choosing the ideal software for PLC programming, ensuring users can make informed decisions that drive productivity and innovation.

PLC Programming Software

PLC programming software enables programmers to create, debug, and implement control systems for industrial automation. This software serves as a vital tool for engineers and technicians, streamlining the design and management of complex processes. Robust features such as graphical interfaces and simulation capabilities enhance user experience and allow for effective visualization of system operations.

Key Features

- User-Friendly Interface: Simplifies navigation and reduces the learning curve.

- Real-Time Monitoring: Provides immediate feedback on system performance.

- Debugging Tools: Identifies and resolves issues efficiently, minimizing downtime.

- Simulation Environment: Allows testing of programs without affecting actual systems.

Benefits

- Increased Efficiency: Automates repetitive tasks, conserving time and resources.

- Enhanced Flexibility: Adapts to changing production requirements seamlessly.

- Improved Accuracy: Reduces human error through automation and validation features.

- Support for Multiple Protocols: Integrates various communication standards, enhancing interoperability.

Considerations

- Compatibility: Ensures alignment with existing hardware and systems.

- Cost: Evaluates software pricing when making procurement decisions.

- Vendor Support: Assesses the availability of training and technical assistance.

Selecting the appropriate PLC programming software can significantly impact operational productivity and innovation within an organization. The right choice supports improved processes and aligns with strategic objectives for automation.

Features of PLC Programming Software

PLC programming software offers a range of features that enhance usability and functionality, driving productivity in industrial automation. These capabilities cater to diverse user needs and improve system efficiency.

User Interface

User-friendly interfaces streamline the programming process. Visual elements such as drag-and-drop functionality allow users to build programs intuitively. Customizable toolbars and contextual menus provide quick access to frequently used features. Intuitive layouts reduce the learning curve for new users, enabling rapid adoption and improved workflow. Real-time feedback and error highlighting enhance the programming experience, providing instant responses to user actions.

Programming Languages Supported

PLC programming software supports multiple programming languages to accommodate various preferences and industry standards. Common languages include:

- Ladder Logic (LD): A graphical representation resembling electrical relay logic, ideal for control circuits.

- Structured Text (ST): A high-level textual language suited for complex algorithms and data manipulation.

- Function Block Diagram (FBD): A graphical approach using function blocks, simplifying the representation of processes.

- Sequential Function Charts (SFC): This visual language outlines complex sequential operations effectively.

Compatibility with these languages offers flexibility, allowing programmers to choose the most suitable language for specific applications. The availability of various languages also facilitates collaboration among engineers with different expertise and backgrounds.

Popular PLC Programming Software Options

Several PLC programming software options cater to diverse industrial needs, offering specific features that enhance productivity and operational efficiency. Below are three popular choices:

Software A

Software A, known for its robust features and user-friendly interface, supports multiple programming languages including Ladder Logic and Structured Text. Real-time monitoring capabilities enable users to track system performance effectively. Its advanced debugging tools facilitate the identification and resolution of issues, improving overall workflow. Many users appreciate its compatibility with various hardware platforms, ensuring seamless integration in diverse environments.

Software B

Software B offers a comprehensive suite of tools designed for advanced industrial automation projects. Its visual programming environment simplifies complex tasks with drag-and-drop functionality. Users benefit from powerful simulation and testing features that allow program validation before deployment. Additionally, Software B supports extensive libraries of pre-built functions, streamlining programming for common applications and enhancing efficiency for engineers.

Software C

Software C emphasizes scalability and flexibility, addressing the needs of both small and large operations. It provides multi-user capabilities, allowing teams to collaborate on projects seamlessly. With a focus on security features, it ensures that automation processes remain protected from unauthorized access. It also includes customizable dashboards, which help users monitor key performance indicators in real-time, thus enhancing decision-making processes.

Benefits of Using PLC Programming Software

Using PLC programming software offers several notable advantages that enhance industrial automation processes.

- Increased Efficiency: PLC programming software streamlines the programming and implementation of control systems. Users experience faster development cycles and reduced time in programming tasks.

- Enhanced Flexibility: Various programming languages support provides versatility in system design. Engineers can choose the approach that best suits their workflow, allowing for effective collaboration across teams.

- Improved Accuracy: Advanced debugging tools within the software detect and eliminate errors quickly. This capability ensures that control systems operate as intended, minimizing the risk of costly mistakes in production environments.

- Support for Multiple Communication Protocols: PLC programming software typically supports various communication protocols, facilitating integration with different hardware components. This interoperability promotes seamless connectivity within automation systems.

- Real-Time Monitoring: The ability to monitor system performance in real time allows for immediate adjustments and troubleshooting. This feature contributes to maintaining optimal operational conditions and mitigating downtime.

- User-Friendly Interfaces: Designed with simplicity in mind, PLC programming software often includes drag-and-drop functionalities and customizable dashboards. These interfaces lower the learning curve, making it easier for new users to adopt the technology.

- Simulation Capabilities: Simulation tools enable users to test systems under various scenarios before implementation. This capability enhances planning accuracy and reduces the likelihood of unexpected issues during runtime.

- Scalability: As production demands increase, PLC programming software can scale to accommodate larger systems without compromising performance. This scalability ensures continued efficiency throughout growth phases.

The combination of these benefits significantly improves operational effectiveness and supports strategic automation initiatives within various industrial environments.

PLC programming software plays a crucial role in modern industrial automation. By streamlining processes and enhancing operational efficiency, these tools empower engineers and technicians to create and troubleshoot control systems effectively.

With features like user-friendly interfaces and advanced debugging capabilities, this software not only reduces downtime but also boosts productivity. Choosing the right PLC programming software can significantly impact an organization’s automation goals.

Investing time in understanding the available options ensures that businesses can select solutions that align with their specific needs and promote sustainable growth. As industries continue to evolve, the importance of effective PLC programming software will only increase.